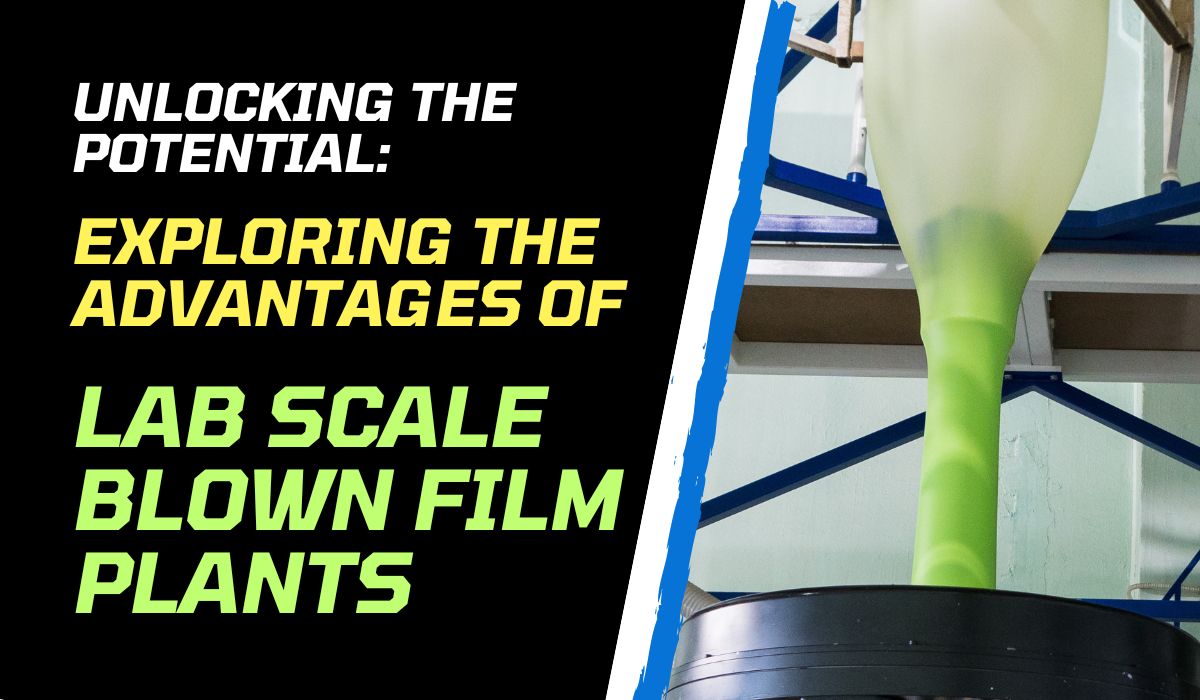

In today’s competitive manufacturing landscape, staying ahead requires continuous innovation and optimization. Lab scale blown film plants have emerged as a game-changer, offering immense possibilities for research, development, and quality control. This article delves into the advantages of these advanced lab-scale plants, shedding light on how they can unlock untapped potential for manufacturers.

Lab scale blown film plants enable manufacturers to simulate real-world conditions in a controlled environment. This empowers them to test new formulations, evaluate material performance, and troubleshoot existing processes with ease. By identifying and rectifying issues in the lab, manufacturers can minimize downtime, improve productivity, and reduce material wastage.

Moreover, lab scale blown film plants offer flexibility, allowing manufacturers to experiment with various polymers, additives, and processing parameters without interrupting their regular production lines. The ability to accurately replicate production conditions on a smaller scale facilitates faster iterations, enabling manufacturers to test multiple hypotheses and develop optimized solutions more efficiently.

In conclusion, embracing lab scale blown film plants unlocks a world of advantages for manufacturers. By harnessing these plants’ capabilities for research, development, and quality control, manufacturers can propel their businesses forward, achieving enhanced productivity, cost savings, and ultimately, a competitive edge in the market.

Understanding the advantages of lab scale blown film plants

Lab scale blown film plants are revolutionizing the way manufacturers approach film production. One of the primary advantages they offer is the ability to conduct experiments in a controlled setting, mimicking the actual conditions of large-scale production without the associated risks and costs. This controlled environment allows for precise adjustments and measurements, enabling researchers to gain invaluable insights into material performance and processing efficiency. As a result, manufacturers can identify optimal parameters that lead to enhanced product quality and performance.

Another significant advantage of lab scale blown film plants is their ability to accelerate the research and development process. With the capability to produce small batches of film quickly, manufacturers can iterate through various formulations and processing conditions in a matter of days rather than weeks. This rapid prototyping not only shortens the product development timeline but also reduces the amount of material wasted during the trial-and-error phase. Consequently, businesses can respond to market demands more swiftly, adjusting their offerings to meet evolving customer preferences.

Additionally, lab scale blown film plants facilitate collaboration across different departments, such as R&D, production, and quality assurance. By providing a common platform for testing and validating new ideas, these plants encourage teamwork and innovation. Employees from various backgrounds can come together to analyze data, share findings, and refine processes, ultimately leading to a more cohesive approach to product development. This collaborative environment fosters a culture of continuous improvement, essential for staying competitive in today’s fast-paced manufacturing landscape.

The importance of film quality in the packaging industry

In the packaging industry, film quality is paramount. Packaging materials must not only protect the product but also maintain its integrity and longevity. High-quality films provide essential barriers against moisture, oxygen, and light, which can deteriorate the contents over time. The importance of film quality extends beyond mere protection; it directly impacts consumer perception and brand reputation. Poor-quality films can lead to spoilage, waste, and ultimately loss of customer trust, making it crucial for manufacturers to prioritize quality at every stage of production.

Moreover, film quality plays a significant role in operational efficiencies. When manufacturers invest in high-quality films, they reduce the likelihood of production interruptions caused by film failures or defects. This translates to lower production costs and increased profitability, as manufacturers can maintain higher throughput rates and minimize the need for rework. Additionally, quality films often exhibit better mechanical properties, such as tensile strength and elongation, which can enhance the overall performance of the packaging during handling and transportation.

To ensure film quality, manufacturers must engage in rigorous testing and validation processes. Lab scale blown film plants serve as an ideal platform for conducting these assessments. By simulating real-world conditions and testing various formulations, manufacturers can identify the best materials and processing parameters that yield superior film quality. This proactive approach not only enhances product performance but also positions manufacturers as leaders in the packaging industry, ready to meet the demands of an increasingly discerning market.

Cost-effectiveness of lab scale blown film plants

Investing in a lab scale blown film plant can be highly cost-effective for manufacturers, particularly in the early stages of product development. Traditional blown film production processes require significant capital investment in large machinery and infrastructure. In contrast, lab scale plants allow manufacturers to produce small quantities of film at a fraction of the cost, facilitating experimentation without the financial burdens associated with full-scale production. This ability to test ideas without heavy investment is especially valuable for startups and smaller companies looking to innovate.

Furthermore, lab scale blown film plants contribute to cost savings by minimizing material waste. In large-scale production, any errors or defects can lead to substantial losses, as entire batches may need to be discarded. With lab scale plants, manufacturers can conduct experiments and trials with small quantities, ensuring that only minimal amounts of material are used during the development process. This not only conserves resources but also translates to lower overall production costs.

Additionally, the insights gained from lab scale experiments can lead to more efficient production processes. By optimizing formulations and processing parameters in the lab, manufacturers can implement changes that enhance the efficiency of their full-scale operations. These improvements can result in reduced energy consumption, lower labor costs, and decreased maintenance expenses, further contributing to the overall cost-effectiveness of adopting lab scale blown film plants.

Flexibility and customization options offered by lab scale blown film plants

One of the standout features of lab scale blown film plants is their inherent flexibility. Manufacturers can experiment with a wide variety of polymers, additives, and processing conditions without interrupting their regular production lines. This adaptability allows for the rapid testing of new materials and formulations, enabling companies to stay ahead of industry trends and customer demands. Whether it’s developing biodegradable films or enhancing barrier properties, lab scale plants provide the versatility needed to explore multiple avenues for innovation.

Customization is another key advantage of lab scale blown film plants. These facilities enable manufacturers to tailor their production processes to meet specific requirements, whether for unique applications or niche markets. By adjusting parameters such as temperature, pressure, and cooling rates, manufacturers can produce films with varying characteristics, such as thickness, strength, and transparency. This level of customization is crucial in industries where specific performance criteria are essential, such as food packaging, medical supplies, and industrial applications.

Moreover, the flexibility of lab scale blown film plants fosters a culture of experimentation. Manufacturers can quickly pivot to test new ideas without the constraints of existing production schedules. This agility in the lab allows companies to respond to market feedback and consumer preferences more effectively. As a result, manufacturers can introduce innovative products faster, enhancing their competitive edge in a dynamic marketplace where consumer needs are constantly evolving.

Exploring the research and development applications of lab scale blown film plants

Lab scale blown film plants are invaluable tools for research and development (R&D) applications in the plastics industry. They provide a platform for scientists and engineers to explore new polymers and additives, facilitating the development of advanced materials tailored to specific applications. For instance, researchers can investigate the effects of different polymer blends on film properties, such as flexibility, durability, and barrier performance. This exploration is critical for developing next-generation materials that meet the rigorous demands of modern applications.

Moreover, lab scale blown film plants allow for the evaluation of innovative processing techniques. Manufacturers can experiment with various extrusion methods, cooling technologies, and additional processing steps to optimize film production. This experimentation can lead to significant advancements in process efficiency, reducing cycle times and energy consumption while improving overall product quality. The insights gained from these R&D activities can inform larger-scale production strategies, ensuring that innovations are seamlessly integrated into existing operations.

Another critical aspect of R&D in blown film production is the testing of new applications. As industries evolve, the need for specialized films becomes apparent, whether for sustainable packaging solutions or advanced medical applications. Lab scale blown film plants enable manufacturers to prototype these specialized films quickly, allowing for rapid testing and validation of performance criteria. This ability to address market demands swiftly can position manufacturers as leaders in their respective fields, paving the way for future growth and innovation.

Comparison between lab scale and industrial scale blown film plants

When comparing lab scale and industrial scale blown film plants, several key differences emerge that highlight the unique advantages of each. Lab scale plants are designed for experimentation and research, enabling manufacturers to produce small batches of film for testing and validation. This small-scale operation allows for rapid prototyping and iterative development, facilitating the exploration of new materials and formulations without the risk of significant financial loss. In contrast, industrial scale plants are built for high-volume production, focusing on efficiency and output to meet commercial demands.

Another critical distinction lies in the level of control and customization offered by lab scale blown film plants. These facilities allow for precise adjustments to processing parameters, enabling manufacturers to fine-tune their productions for specific applications. This increased control is essential for developing specialized films that may require unique properties or characteristics. On the other hand, industrial scale plants prioritize throughput and may have limitations in terms of flexibility, making it challenging to accommodate small batch runs or experimental formulations.

However, while lab scale plants excel in R&D applications, industrial scale plants are vital for bringing successful innovations to market. Once a new material or process has been validated in the lab, manufacturers can transition to industrial scale production to meet the demands of their customers. This seamless integration between lab and industrial scale operations is essential for driving innovation in the blown film industry, ensuring that new ideas can be scaled up efficiently and effectively.

Factors to consider when investing in a lab scale blown film plant

Investing in a lab scale blown film plant is a significant decision that requires careful consideration of various factors. First and foremost, manufacturers should evaluate their specific needs and objectives. Understanding the primary purpose of the lab scale plant—whether for R&D, quality control, or both—will guide the selection of equipment and features necessary for achieving desired outcomes. A clear understanding of goals will also help in determining the budget and resources required for the investment.

Another critical factor to consider is the level of technical support and training available for the equipment. Lab scale blown film plants often come with complex machinery that requires skilled operators to maximize their potential. Manufacturers should ensure that the supplier offers comprehensive training programs and ongoing technical support to facilitate smooth operation and maintenance. This investment in human capital is essential for ensuring that the plant operates efficiently and effectively while maximizing the return on investment.

Additionally, manufacturers should assess the scalability of the lab scale blown film plant. As businesses grow, their R&D needs may evolve, necessitating the expansion of testing capabilities. Selecting a plant that can be easily upgraded or integrated with existing equipment will provide long-term benefits, allowing manufacturers to adapt to changing market conditions. This forward-thinking approach will ensure that the investment in lab scale technology remains viable and beneficial for years to come.

Case studies showcasing the success of lab scale blown film plants

Examining case studies of companies that have successfully integrated lab scale blown film plants into their operations can provide valuable insights into their potential advantages. One notable example is a packaging manufacturer that sought to develop a new line of sustainable films made from biodegradable materials. By utilizing a lab scale blown film plant, the company was able to experiment with various polymer blends and processing conditions, ultimately creating a high-quality film that met both performance and environmental standards. This successful development not only enhanced the company’s product offerings but also positioned it as a leader in sustainable packaging solutions.

Another case study highlights the experience of a food packaging company that faced challenges with product spoilage due to inadequate barrier properties in their existing films. By investing in a lab scale blown film plant, the company conducted thorough testing of different polymer formulations and additives. The insights gained from these experiments allowed the company to develop a new film with significantly improved barrier performance, reducing spoilage rates and enhancing customer satisfaction. The ability to troubleshoot and innovate in a controlled environment proved instrumental in the company’s success.

Lastly, a medical supplies manufacturer leveraged a lab scale blown film plant to accelerate the development of specialized films for sterile packaging. By rapidly prototyping and testing various formulations, the company was able to create films that met stringent industry regulations for safety and performance. This efficient R&D process not only reduced time-to-market but also ensured that the company could respond swiftly to the growing demand for medical supplies during critical periods, showcasing the potential for lab scale plants to drive innovation in high-stakes industries.

Conclusion: Embracing the potential of lab scale blown film plants for innovation and growth

In conclusion, lab scale blown film plants represent a powerful tool for manufacturers looking to innovate and grow in an increasingly competitive market. The advantages they offer—ranging from controlled experimentation and rapid prototyping to enhanced film quality and cost-effectiveness—are invaluable in today’s fast-paced manufacturing landscape. By embracing these advanced facilities, companies can streamline their R&D processes, reduce material waste, and enhance product offerings while maintaining a sharp focus on quality.

Moreover, the flexibility and customization options provided by lab scale blown film plants empower manufacturers to respond to evolving market demands swiftly. As industries continue to change, the ability to experiment and adapt will be crucial for maintaining a competitive edge. The insights gained from lab-scale experiments not only drive innovation but also ensure that manufacturers remain well-equipped to meet the diverse needs of their customers.

Ultimately, investing in lab scale blown film plants is an investment in the future. The case studies and success stories shared throughout this article illustrate the transformative potential these facilities can deliver. By harnessing the capabilities of lab scale technology, manufacturers can unlock new opportunities for growth, enhance their product offerings, and pave the way for a more sustainable and innovative future.

Leave A Comment